Delivering High-Tolerance Machining You Can Trust

In today’s competitive manufacturing environment, high-tolerance machining isn’t just about precision it’s about confidence, reliability, and performance.

Customers in aerospace, medical, and advanced manufacturing rely on components that meet exact specifications, because even the smallest deviation can affect safety, functionality, and product lifespan. That’s why high-tolerance quality is at the core of everything we do.

We start by fully understanding your design intent, not just your drawings. Our engineering team reviews tolerances, critical features, and functional requirements to ensure every part performs exactly as intended in its final application.

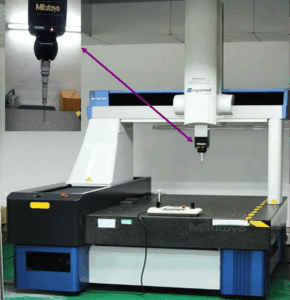

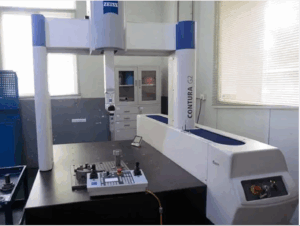

Our facilities are equipped with advanced CNC machining centers, maintained and calibrated to deliver consistent accuracy on the most demanding components. Controlled environments, proven machining strategies, and premium tooling allow us to hold tight tolerances repeatably from prototype through full production.

Quality is built into the process, not inspected in at the end. We use in-process measurement, advanced inspection equipment, and documented quality systems to verify accuracy at every stage. This proactive approach reduces risk, minimizes scrap, and ensures on-time delivery.

What truly sets us apart is our commitment to precision and accountability. Every high-tolerance part we deliver reflects our focus on process control, skilled craftsmanship, and continuous improvement.

When precision matters and tolerances are tight, you need a machining partner you can trust to get it right the first time and every time.